Causes of crop spoilage in the vegetable storehouse

15.10.2021 | Vegetable storage

Listed below are the various sources that cause spoilage of fruits and vegetables during long-term storage and the corrective measures that should be taken to minimize and mitigate the effects.

1. Mechanical damage.

Causes:

- Improper harvesting methods;

- Poor handling, threshing, husking, cleaning, grading, or drying;

- Traumatic methods of transportation and loading (e.g. use of hooks).

- Weight loss;

- Loss of quality (nutritional value, appearance);

- Increased vulnerability to infestation by insect pests and fungi.

- Pay attention to maximum temperatures when drying!

- Use safe methods when harvesting, transporting, processing and storing;

- Use caution when handling bags or crates;

- Repair or replace damaged bags or crates;

- Do not use hooks to carry bags or crates;

- Keep an eye on the condition of pallets (e.g., remove protruding nails).

2. High temperature

Causes:

- Inappropriate storage design (improper location, insufficient shade and ventilation facilities, lack of insulation);

- Mass reproduction of pests and fungi;

- Insufficient aeration of the storage room;

- High level of humidity.

- Weight loss;

- Loss in quality (nutritional value, appearance);

- Good conditions for the development of pests;

- Moisture condensation, followed by fungal development.

- Approach the design of vegetable storage very responsibly - this will help avoid most mistakes!

- Provide shade for the storage units or silos (e.g. with wide eaves or shading trees);

- Maintain an optimal temperature (ventilate the storage facility);

- Conduct pest control treatments;

- Store bags or boxes on pallets to improve aeration;

- Maintain a space of 1 m around all stacks.

3. High humidity

Causes:

- Insufficient drying before storage;

- High relative humidity in the room;

- Structural defects and damage to the storage room (unsuitable materials, leaky floor, walls and roof, holes, cracks, etc.);

- Temperature imbalances (e.g., day/night) in the storage room followed by condensation;

- Mass reproduction of pests.

Consequences:

- Loss in quality;

- Loss in weight;

- Fungal development and formation of mycotoxins;

- Swelling and germination;

- Damage to the storage structure.

- Dry produce well before storage;

- Repair and seal the storage facility;

- Keep the relative humidity in storage as low as possible (option: controlled atmosphere);

- Store bags or crates on pallets;

- Provide a space of 1 m around all stacks;

- Conduct pest control treatments;

- Avoid temperature differences (day/night) in the storage area by ventilation.

4. Insect pests

Causes of infestation:

- Introduction from infested lots, cross-infestation from neighboring lots or storage facilities;

- Migration from waste or garbage

- Use of infested bags or crates.

- Loss in weight;

- Loss of quality (impurities such as droppings, cocoons and insect parts, reduced nutritional value, threat to the health of the end user);

- Increased temperature and humidity.

- Harvest at the right time;

- Choose resistant varieties;

- Keep transportation equipment clean;

- Remove infected fruit before storage;

- Make sure produce is dry before putting in storage;

- Prevent the introduction of pests by checking for infestations before storage;

- Clean the storage room daily;

- Keep the temperature and relative humidity as low as possible (option: controlled atmosphere);

- Prevent pests from entering by sealing the storage area (windows, doors, vents);

- Repair any damage to the storage area immediately;

- Store old and new batches separately;

- Clean empty bags and crates thoroughly and treat them against insects if necessary;

- Conduct pest control treatments;

- Rotate supplies on a first-come, first-served basis.

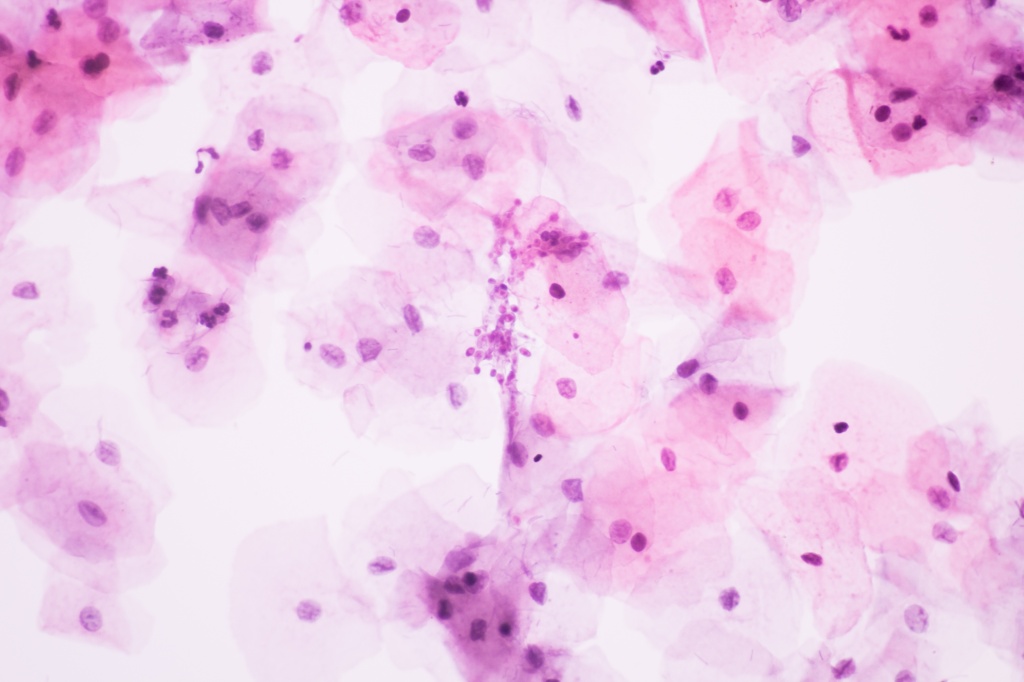

5. Microorganisms

Causes of contamination:

- High moisture content in stored produce;

- High relative humidity in storage;

- Condensation;

- Humidity and dampness caused by insects.

- Loss of quality (smell, taste, color, nutritional value);

- Formation of mycotoxins;

- Slight weight loss (mold);

- Further increase in temperature and humidity;

- Further condensation.

- Sufficiently dry produce before storage;

- Keep the relative humidity in storage as low as possible (controlled atmosphere);

- Store bags and crates on pallets;

- Allow 1 m space around all stacks;

- Conduct pest control treatments.

6. Rodents

Causes of Infestation:

- Penetration of rodents through poorly closed doors, windows, vents, holes;

- Lack of barriers;

- Lack of hygiene in the storage facility and the surrounding area (possible hiding and breeding places).

- Weight loss;

- Large quality losses due to contamination of produce with feces and urine;

- Product contamination by pathogenic agents (typhoid, rabies, hepatitis, plague, etc.);

- Damage to materials and equipment (bags, crates, doors, electrical cables).

- Prevent rodent entry by sealing the storage facility from rats;

- Keep the storage facility and surrounding area clean;

- Place traps;

- Carry out rodent control measures.

7. Birds

Causes:

- Open or broken doors, windows, vents or roofs.

- Consequences:

- Weight loss;

- Damage to bags or crates;

- Contamination of stored produce with manure and pathogenic agents.

- Protect storage facilities from birds (make repairs, install grates or nets);

- Remove all bird nests from the storehouse and surrounding area.