Technology

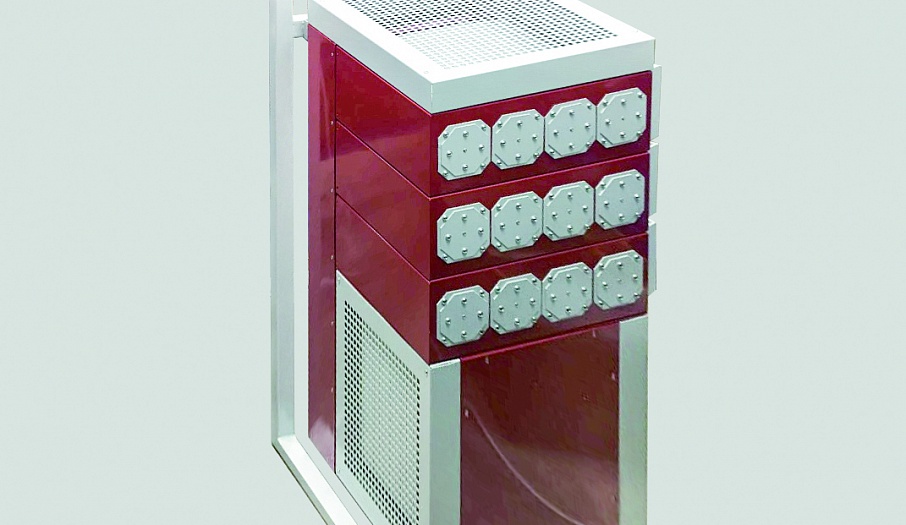

Agrovent Elpida one Air Cleaner

The Agrovent Elpida one technology offers reduction of economic losses in your vegetable / fruit storage up to 90%. Compared to the ozone treatment methods, the air cleaner can operate day and night without causing any harm to people in the room. Your products will be always protected against pathogenic bacteria, fungi, and moulds.

OPERATING PRINCIPLE

The device operation is based on the photocatalytic oxidation of organic compounds on the nanocrystalline titanium dioxide surface caused by “soft” (315-405 nm) UV radiation. The oxidation products are mainly water vapor and carbon dioxide. Please note that the air organic pollutants are not accumulated on the photocatalytic filters or inside the devices.

PURPOSE

Application of our productswill enable you to:

-

Remove harmful bacteria in the air;

-

Reduce risk of phytopathogens influence;

-

Decrease distribution of bacteria and fungus diseases in the air;

-

Improve air quality inside the storage;

-

Create a friendly environment for vegetables and fruits storage.

How does the air photocatalytic cleaning and decontamination system work?

The principle of the device operation is based on catalyzation. A catalyst is a substance that stimulates and accelerates the chemical reaction, although remains unconsumed.

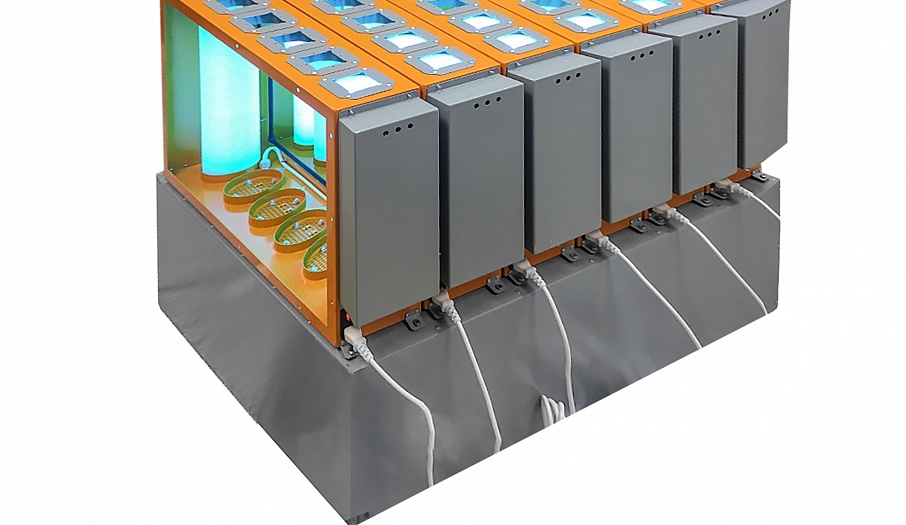

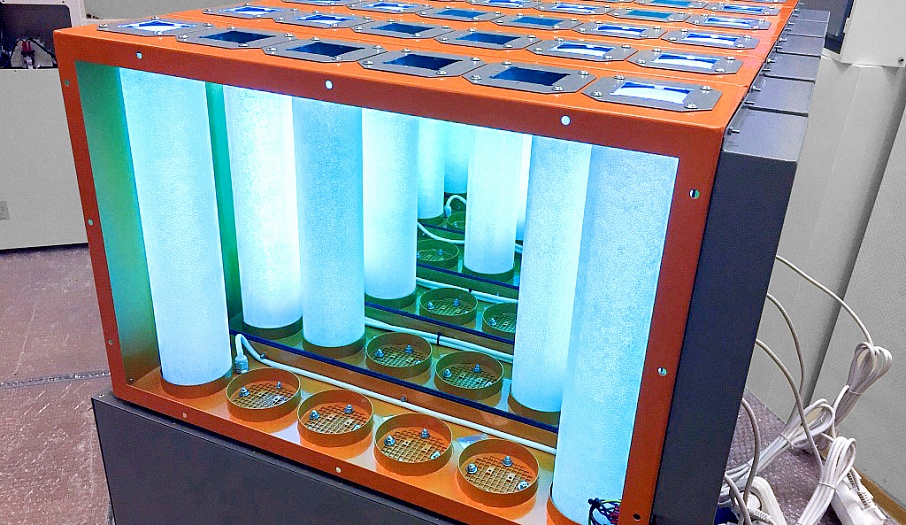

The filtering system of the photocatalytic cleaner use two main elements: ultraviolet and catalyst.

A light transmitting porous glass is used in the device as the filter. With its high absorbing properties, the glass retains particles from the air. As the catalyst, titanium dioxide which coats the glass with thin layer is used.

The device operates as follows: the cleaner absorbs air, the filter retains various particles, ultraviolet radiation is directed to the filter with catalyst. Under influence of the strong UV light, titanium dioxide activates oxidation processes on its surface. In the course of this reaction, the organic particles caught by the filter decompose into safe components: carbon dioxide and ordinary water. The substances break up at the thin molecular level. The gas evaporates immediately and the water evaporates as it dries. In fact, the cleaner does not accumulate pollutants from the atmosphere, however, it collects and immediately destroys them completely. This particular feature determines its high practicality.

The method consists in oxidation of substances on the catalyst surface under influence of soft ultraviolet radiation of the “A” range (with a wave length of more than 300 nm).The reaction proceeds at room temperature; any toxic impurities do not accumulate on the filter, but are destroyed to harmless air components such as carbon dioxide, water and nitrogen. Any photocatalytic air cleaner includes porous carrier coated by ТiО2-photocatalyst which is irradiated with light and blown through by the air.

The harmful organic and nonorganic pollutants, bacteria, and viruses are adsorbed on the surface of the ТiО2-photocatalyst applied to the porous carrier (photocatalytic filter). Under influence of UV lamp of the “A” range, their organic and nonorganic components oxidize to carbon dioxide and water. In fact, photocatalysis provides a unique opportunity to deeply oxidize organic compounds under mild conditions. Due to simplicity of the devices themselves, excellent results of using this method in practice are expected.

Around the storage perimeter, 6 Agrovent Elpida one units were placed to clean and decontaminate the air in closed premises by means of photocatalytic oxidation of the organic compounds. The oxidation products are mainly water vapor and carbon dioxide. One unit capacity was 400 m3/h. In addition, the potato tubers affected by bulb eelworm, fusarium dry rot, and blackleg were placed in each unit.

Air decontamination and cleaning devices significantly improve the air quality in vegetable storage by reducing content of bacterium and other organic pollutant particles as well as by protecting the products from phytopathogens and bacterial and fungus diseases.

Storage Technology

A combination ventilation system provides for air circulation through produce containers and replaces excessive levels of carbon dioxide and the other byproducts of produce respiration with the outside air.

Underfloor ducts provide air circulation through produce with the help of underfloor air ducts, create uniform temperature and moisture...

A pressure system is used only for the container storage of vegetables and is one of today’s most effective systems.

This storage technology is one of the most advanced found on today’s market.

The Agrovent Elpida one technology offers reduction of economic losses in your vegetable / fruit storage up to 90%. Compared to the ozone treatment methods, the air cleaner can operate day and night without causing any harm to people in the room.

Blog

Storage technology