Technology

A combination ventilation system provides for air circulation through produce containers and replaces excessive levels of carbon dioxide and the other byproducts of produce respiration with the outside air. The combination system is the result of combining of an air cooler with plenum valves. As a result, additional fans are not necessary. As a rule, the combination system is used for small storage capacities.

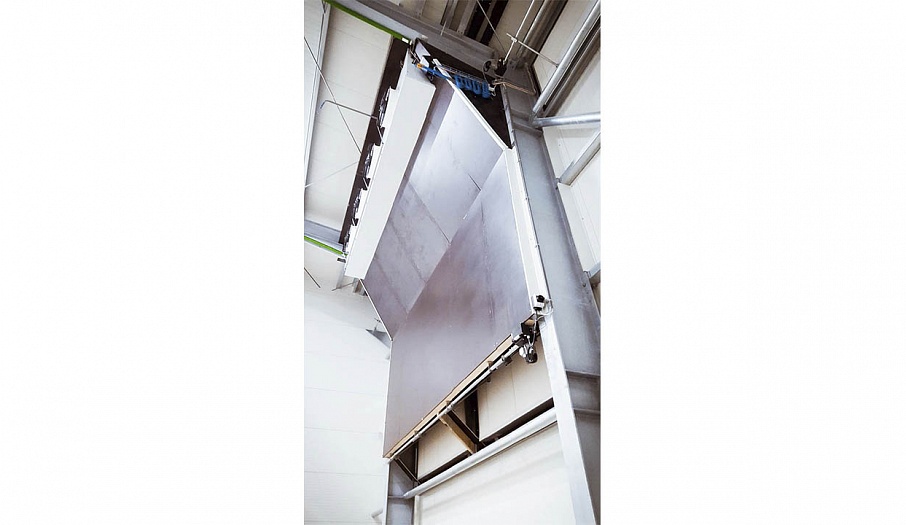

Combination ventilation

In storage rooms where refrigerating equipment is needed, a ventilation system that delivers and removes fresh air should be installed. In winter when the temperature is lower than the storage temperature, the system uses cold air for cooling and maintaining the temperature of produce without refrigeration equipment. A refrigeration system is used when storing at high outer temperatures (in April, May, June) or when the temperature of produce has to be decreased in a short period of time like during crop harvest or while putting produce into storage. Artificial air cooling in a storage using a refrigeration system is designed in such a way so as to avoid impacting produce quality and minimize produce crusting and drying.

.png)

The required storage parameters are maintained with an automatic control system which was specially designed for vegetable storages. The information can be automatically sent from a controller to a PC or smartphone with an option for remotely monitoring and regulating storage parameters.

The principle of ventilation arrangement

The air combination chamber is located between the outer wall of the building and the air cooler. Air cooler fans provide for air circulation. If cold air from the outside is needed, the plenum valve automatically ajars at a certain angle.

The plenum valve blocks the flow of recirculated air from the chamber, thereby providing for the mixing of recirculated air and outside air until the required temperature is reached and excluding freezing. Valves for air removal are also installed in the chamber. Under excess pressure, the warm air is removed from the chamber.

The required storage parameters are maintained with an automatic control system for ventilation, humidification, refrigeration and heating. The opening of valves is regulated with an electric drive, which changes the opening angle depending on the temperature.

Refrigeration

A refrigeration system is used when storing at high outer temperatures (in April, May, June) or when the temperature of produce has to be decreased in a short period of time like during crop harvest or while putting produce into storage.

Artificial air cooling in a storage using a refrigeration system is designed in such a way so as to avoid impacting produce quality and minimize produce crusting and drying.

For this purpose, the system uses air coolers that have been specially designed for the storage of fruits and vegetables. They feature an enlarged heat-exchange finning surface and low air consumption, an enlarged fin pitch and “corridor” pipe pitch in the cooler housing, thereby achieving the lowest-possible “temperature drag.”

The specific arrangement of fans near the entrance to the air cooler provides the air drag into the heat exchanger of the air cooler, which decreases condensate falling onto the surface of the produce and lowers the rate of produce drying. It is extremely important that the minimum temperature drop in air coolers should be less than 6 degrees (Dt6k), which means that the boiling temperature of freon gas should be 6 degrees lower than the temperature in a chamber.

Automation

The required storage parameters are maintained with an automatic control system which was specially designed for vegetable storages.

It provides for the:

- Control of storage modes;

- Control of the refrigeration system;

- Control of the humidification system;

- Control of drying modes;

- Data collection and archiving;

- Monitoring and remote control.

The required storage parameters are maintained with an automatic control system which was specially designed for vegetable storages. The information can be automatically sent from a controller to a PC or smartphone which can be used for the remote monitoring and maintenance of storage parameters.

Recommendations

- The length of a chamber should be no more than 20-25m

- Storage capacity is no more than 1000 tons

- It is used for storing cabbage, carrots and a small quantity of potatoes

Blog

Storage technology

Rectangular building conveniently

Reconstruction building

Container storage